Hydraulic frame machines offer more than just heavy-duty auto body repair; they're versatile tools for aligning frames, correcting damage, and performing precise panel replacements, benefiting various sectors from automotive aftermarkets to custom motorcycle builds. These machines significantly enhance efficiency, reduce error, and achieve remarkable accuracy in repairs across all vehicle types, ensuring high-quality results for satisfied customers.

“Unraveling the mysteries behind hydraulic frame machines (HFMs) is essential for businesses seeking efficient solutions. This article aims to dispel common myths and showcase the versatility of HFMs in various industries. From construction to manufacturing, these powerful tools offer unprecedented precision and control. By exploring real-world applications and backed by factual data, we’ll demonstrate why HFMs are a game-changer, challenging the misconceptions and highlighting their potential to revolutionize operations.”

- Common Misconceptions About Hydraulic Frame Machines

- Real-World Applications: Beyond the Myths

- Unlocking Efficiency: Facts and Figures

Common Misconceptions About Hydraulic Frame Machines

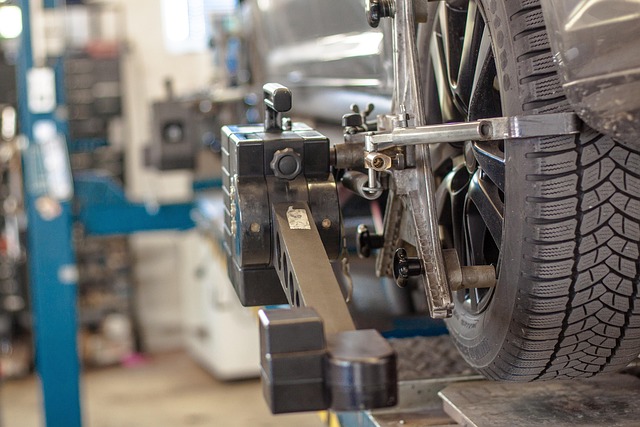

Many people often hold onto misconceptions about hydraulic frame machines and their applications, especially within the context of auto body shops and car dent repairs. One common mistake is assuming that these machines are solely reserved for heavy-duty tasks and cannot be utilized in everyday auto repair processes. However, this couldn’t be further from the truth. Hydraulic frame machines offer a versatile range of functions, from aligning frames and correcting structural damage to performing precise adjustments during panel replacement, making them indispensable tools in modern auto body shops.

Another misconception is that these machines are only necessary for large-scale repairs, which couldn’t be less accurate. Even minor incidents like a car dent repair can benefit from the precision and efficiency of hydraulic frame machines. The ability to quickly and accurately restore a vehicle’s structural integrity makes them an invaluable asset for any auto repair near me service provider, ensuring high-quality results and customer satisfaction.

Real-World Applications: Beyond the Myths

In reality, hydraulic frame machines are versatile tools that go beyond the myths often associated with them. These machines play a pivotal role in various industries, especially in the realm of auto body repair and collision centers. Beyond straightening vehicle frames after accidents or collisions, they are utilized for intricate metal fabrication tasks. Auto collision centers appreciate their efficiency in shaping and forming metal panels, ensuring precise alignments during the auto body repair process.

The applications extend to custom fabrication and even artistic metalwork. Many skilled technicians in collision repair shops have harnessed the power of hydraulic frame machines to create unique designs, from automotive aftermarkets to custom motorcycle builds. This versatility challenges the notion that these machines are limited to basic frame straightening, showcasing their potential to revolutionize various aspects of metalworking within the auto body repair sector.

Unlocking Efficiency: Facts and Figures

The hydraulic frame machine is a game-changer in the automotive industry, particularly for autobody repairs. While myths persist about its limitations, facts reveal a different story. This advanced technology offers unparalleled precision and efficiency in tasks like frame straightening, making it a cornerstone of modern repair shops.

Studies show that hydraulic frame machines can significantly reduce repair times by up to 50% compared to manual methods. They achieve this through consistent force application, minimizing human error. Moreover, these machines are versatile; they can handle various vehicle types and sizes, from compact cars to heavy-duty trucks. In the realm of scratch repair, hydraulic frame machines prove invaluable, allowing for meticulous adjustments and restoring vehicles to their pre-incident condition with remarkable accuracy.

In dispelling myths and exploring facts, it’s clear that hydraulic frame machines offer a versatile and efficient solution across diverse industries. Beyond common misconceptions, these powerful tools have proven their worth in numerous real-world applications, from construction to manufacturing. Unlocking efficiency through hydraulic technology, these machines streamline processes, enhance productivity, and contribute to cost savings, making them an indispensable asset for modern workshops and job sites alike.