Hydraulic frame machines are versatile tools that have revolutionized precision work in modern workshops. These powerful machines, with their advanced hydraulic systems, offer unprecedented control and accuracy for technicians across various industries. From metal fabrication to woodworking, understanding how hydraulic frame machines function is key to unlocking their efficiency. This article explores the technical aspects, diverse applications, and benefits these machines bring to technicians, enhancing productivity and precision in today’s demanding work environments.

- Understanding Hydraulic Frame Machines: A Technical Overview

- Applications in Precision Work: Unlocking Efficiency and Accuracy

- Benefits and Considerations for Technicians in Modern Workshops

Understanding Hydraulic Frame Machines: A Technical Overview

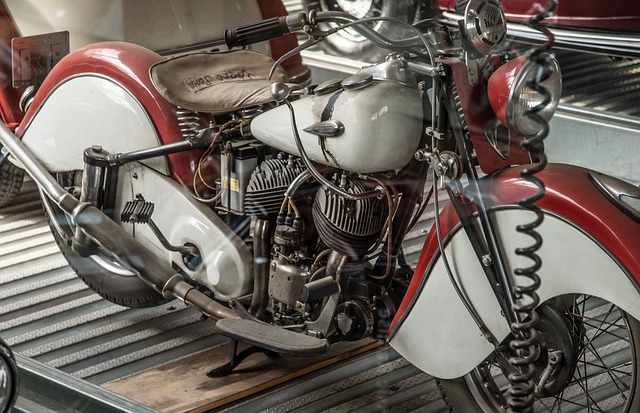

Hydraulic frame machines are advanced pieces of equipment designed to handle precise and intricate tasks in various industries, including automotive and vehicle restoration. These machines operate using hydraulic power, which translates to exceptional control and force when performing delicate operations. The core component is a robust frame equipped with hydraulic cylinders that enable linear movement, allowing for complex manipulations. This technology is invaluable in auto glass repair, where precision is paramount to ensure the safety and integrity of the vehicle’s structure.

Moreover, their versatility extends to classic car restoration projects, demanding meticulous attention to detail. Technicians can precisely adjust and manipulate components, recreating historical accuracy with remarkable efficacy. In vehicle bodywork, these machines streamline processes like panel bending and shaping, enhancing both efficiency and quality. The hydraulic system’s ability to generate substantial force while maintaining fine control makes it an indispensable tool for achieving exceptional outcomes in various precision-based endeavors.

Applications in Precision Work: Unlocking Efficiency and Accuracy

Hydraulic frame machines are indispensable tools for technicians across various industries, particularly in precision work. These advanced machines offer unparalleled control and accuracy, enabling professionals to perform intricate tasks with ease. From automotive repairs to manufacturing, the applications are vast. In fleet repair services, for instance, hydraulic frames are used to straighten vehicle bodies after collisions, ensuring that every curve and angle is restored to its original specifications, akin to a Mercedes Benz collision repair.

The precision afforded by these machines not only enhances the quality of work but also streamlines the process. Collision repair services, for example, benefit from the efficiency of hydraulic frames in reshaping metal panels, aligning frames, and ensuring structural integrity. This level of accuracy translates into cost savings, reduced downtime for vehicles, and ultimately, happier clients.

Benefits and Considerations for Technicians in Modern Workshops

In modern workshops, technicians reap significant benefits from integrating hydraulic frame machines into their toolsets. These versatile machines streamline various precision tasks, from intricate car body repair to tire services, ensuring meticulous craftsmanship and enhanced efficiency. The hydraulic system’s capacity for precise control allows technicians to manipulate components with unwavering accuracy, reducing the risk of errors often associated with manual labor.

When incorporating these advanced tools, workshops must consider space requirements and initial investment costs. However, the long-term advantages far outweigh these initial challenges. Hydraulic frame machines not only increase productivity but also elevate the quality of work, fostering a competitive edge in an industry where meticulous attention to detail is paramount. This advancement in equipment empowers technicians to offer more comprehensive services, catering to the complex needs of modern vehicle bodywork.

Hydraulic frame machines have emerged as indispensable tools in modern workshops, offering unprecedented precision and efficiency in various tasks. By leveraging this innovative technology, technicians can accomplish complex operations with enhanced speed and accuracy, setting new standards in quality craftsmanship. As these machines continue to evolve, understanding their capabilities and incorporating them into workflow strategies becomes crucial for staying ahead in the industry.