Hydraulic frame machines are indispensable tools in automotive collision repair, offering unparalleled precision, speed, and cost-effectiveness. These machines ensure accurate frame straightening, maintain structural integrity, and streamline the repair process, resulting in improved quality control, reduced downtime, and faster turnaround times for vehicle owners. Their versatility makes them a comprehensive solution for various vehicle types and sizes, enhancing overall workshop productivity and customer satisfaction.

In the realm of repairs, efficiency and precision are paramount. Hydraulic frame machines emerge as indispensable tools, offering a game-changing approach to modern repair practices. These versatile devices play a crucial role in navigating complex tasks, from structural support to precise adjustments. Understanding their operation and benefits is essential for folks seeking optimal outcomes. This article explores why hydraulic frame machine use is vital, highlighting their key advantages and impact on the repair landscape.

- Understanding Hydraulic Frame Machines: Their Role and Advantages in Repairs

- Key Benefits of Using Hydraulic Frame Machines for Repair Work

- The Impact and Importance of Hydraulic Frame Machines in Modern Repair Practices

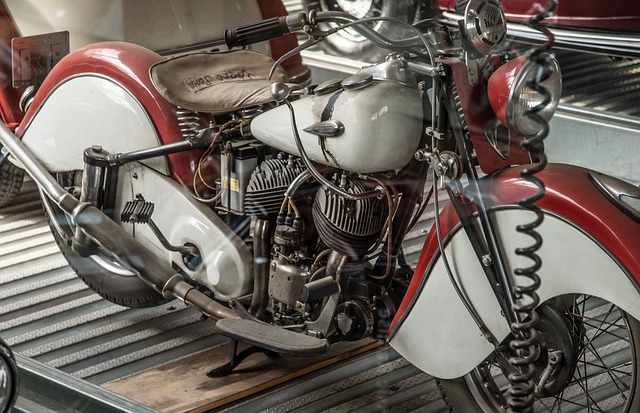

Understanding Hydraulic Frame Machines: Their Role and Advantages in Repairs

Hydraulic frame machines are indispensable tools in the realm of automotive collision repair and vehicle restoration. These innovative devices serve as the backbone for precision alignment and structural integrity during repairs. By leveraging hydraulic power, these machines offer unparalleled control and accuracy when dealing with complex vehicle frames. Their ability to handle heavy loads and adjust with fine tuner ensures that every repair is not just visually appealing but also safe and reliable.

In a collision repair center, the advantages of using a hydraulic frame machine are multifaceted. It streamlines the restoration process, minimizing the time required for repairs without compromising on quality. This results in faster turnaround times, higher customer satisfaction, and cost-effectiveness. Moreover, these machines enable technicians to make intricate adjustments with ease, ensuring that each vehicle leaves the shop as good as new.

Key Benefits of Using Hydraulic Frame Machines for Repair Work

Hydraulic frame machines offer a multitude of benefits that make them an indispensable tool for any automotive repair shop providing top-tier car repair services. Firstly, their precision is unparalleled, allowing for exact frame straightening, which is crucial in ensuring structural integrity after collision repair. This level of accuracy translates into better overall vehicle performance and safety.

These machines also streamline the frame straightening process, significantly reducing the time required compared to manual methods. This efficiency not only benefits the workshop by increasing productivity but also saves customers money. Moreover, hydraulic frame machines are designed for versatility, accommodating various vehicle types and sizes, making them a one-stop solution for all frame-related repair needs in collision repair shops.

The Impact and Importance of Hydraulic Frame Machines in Modern Repair Practices

In modern vehicle repair practices, the hydraulic frame machine plays a pivotal role, revolutionizing how auto body painting and structural repairs are conducted. This advanced piece of equipment is instrumental in ensuring precision, speed, and safety during complex auto repair services. By offering accurate measurements and adjustments, it facilitates precise alignment of vehicle frames, which is crucial for maintaining structural integrity and ensuring the safety of drivers and passengers.

The impact extends beyond mere structural restoration; efficient hydraulic frame machine use contributes to enhanced quality control and reduced downtime. It streamlines the auto repair process, allowing technicians to perform tasks with greater efficiency and accuracy. This not only leads to cost savings for both repair shops and vehicle owners but also results in faster turnaround times, getting vehicles back on the road promptly.

Hydraulic frame machines are revolutionizing repair practices, offering unparalleled precision and efficiency. Their key benefits, from enhanced control to reduced time and material costs, make them an indispensable tool in modern repairs. As technology advances, the importance of these machines will only grow, ensuring faster, more accurate, and cost-effective solutions for years to come.